$624/month through Scotchman Credit Corp. |

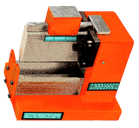

9012-24M |

Share |

Print |

If you are in the medium to large metal fabrication business, the Scotchman 9012-24M hydraulic ironworker will give you the greatest amount of versatility and flexibility on the market today. The Scotchman 9012-24M has a 90-ton Punch Station capable of punching a 1-1/16” hole in 1” thick, 65,000 tensile mild steel. The Flat Bar Shear is 24” wide and is supplied with bar shear blades that can be rotated four times for maximum blade life. The Angle Shear capacity on this machine is 6” x 6” x 1/2”; and like all Scotchman angles shears, it is designed to give a distortion free cut. The 9012-24M hydraulic ironworker has the same large tool table design as the 6509-24M, allowing quick and easy change of optional tooling. Like all Scotchman ironworkers, the 9012-24M is backed by our best-in-the business 3-year warranty!

| Single Operator, 4 Stations |

| 90 Ton Punch Station (1-1/8" in 1") |

| Keyed Punch Ram for Safety |

| 12" Throat Depth |

| Punch Gauging Table with Fence and Scale |

| Die Holder Complete with 2" Die Insert |

| Punch Nut with Wrench & Stripper |

| One Round Punch & Die: Max. Dia. 1-1/4" |

| Punch Jog Control |

| Adjustable Electric Stroke Control with Scale |

| Electric Remote Foot Pedal |

| Angle Shear Capacity 6" x 6" x 1/2" at 90° |

| 24" Flat Bar Shear with 4-Way Reversible Blade (1" x 8", 1/4" x 24") |

| Shear Table with Miter Fence |

| Tool Table Work Area |

| Slug Receptacle |

| Two-Stage Hydraulic Pump |

| Electrical Box Supplied with Emergency Palm Button and Lock-out Tag-out Accommodations |

| 230/460 volt /3 Phase Electrics (must specify voltage) |

| All Guards Necessary to Comply with ANSI B 11-5 Standards |

| Forklift Accommodations |

| Warranty: Three Years on Parts |

| Made in USA |

| Rated on: | 65,000 PSI Tensile | A 36 Mild Steel |

| Punching Capacity | 90 ton

1-1/8" in 1" |

80 mt

27 mm in 25 mm |

| Special Tooling | 4" Max. Dia. | 100 mm Max. Dia. |

| Throat Depth | 12" | 300 mm |

| Flat Bar Shear | 24" Length

1" x 8" 3/4" x 12" 1/2" x 16" 1/4" x 24" |

600 mm

25 mm x 200 mm 18 mm x 300 mm 12 mm x 400 mm 6 mm x 600 mm |

| Opt. Saber Blade | 1/2" x 22"

3/8" x 24" |

12 mm x 550 mm

10 mm x 600 mm |

| Angle Shear 90° | 6" x 6" x 1/2" | 150 mm x 150 mm x 12 mm |

| Angle Shear 45°

(with Bar Shear) |

3" x 3" x 3/8"

4" x 4" x 1/2" |

75 mm x 75 mm x 10 mm

100 mm x 100 mm x 12 mm |

| Brake 12" | 50 ton | 45 mt |

| Brake 24" | 40 ton | 36 mt |

| Open End Brake | Max. 1/4" x 5"

Flat or Angle Iron |

6 mm x 125 mm |

| Pipe Notcher

Schedule 40 I.D. |

3/4"

1" 1-1/4" 1-1/2" 2" |

20 mm

25 mm 32 mm 38 mm 50 mm |

| Rectangle Notcher | 2" x 2-1/2" x 3/8" | 50 mm x 65 mm x 10 mm |

| 90° V. Notcher | 6" x 6" x 5/16" | 150 mm x 150 mm x 8 mm |

| Channel Shear | 2" to 6" Adj. | 50 mm to 150 mm Adj. |

| Unistrut Shear | Samples Required | |

| Rod Shear

Round Rod (Max.) quare Rod (Max.) |

1/4" to 1-1/4", 9 Cav. 1/4" to 1", 1 Cav. |

6 mm to 32 mm 6 mm to 25 mm |

| Square Tube Shear | 1/2" to 2"

12 ga. |

12 mm to 50 mm

2.75 mm |

| Picket Tool | 1/2"

3/4" 1" 16 ga. |

12 mm

19 mm 25 mm 1.6 mm |

| Offset Die Holder | Max. 40 ton | Max. 36 mt |

| Strokes Per Minute in Light Material | 1/4" Stroke [Punch Station] | 56 spm |

| Strokes Per Minute in Heavy Material | 3/4" Stroke [Punch Station] | 19 spm |

| Hydraulics | 2,600 psi | 183 bar |

| Motors Standard | 5 hp 3 ph

230/240 208/380/575 |

3.73 kW |

| Motors Optional | 5 hp 1ph

230v |

3.73 kW |

| Dimensions | W-26"

L-76" H-70" |

W-66 cm

L-193 cm H-177 cm |

| Shipping Weight | 4,204 lbs. | 1,906 kg |

|

LED LightAvailable on punch station and shear station. |

|

Tool Table Extension includes Punch & Die Storage Drawer (65+Ton)*Punches & Dies sold separately. (Watch Movie) |

|

Double Tube PunchCustom built double tube punch. (Watch Movie) |

|

Weld Coupon Bender(Watch Movie) |

|

Angle Iron Miter Guide(Watch Movie) |

|

Punch Table Extension |

|

Round Tube Punch(custom tooling)

|

|

Mandrel Tube Punch (custom tooling)

|

|

24" x 5' Conveyor with Angle Iron Support attached to DO70/110 |

|

Multi-Loc Punch Gauging Table 36" and 85" Extensions Available(Watch Movie) |

|

Unistrut Shear(Watch Movie) |

|

Brake Table with Scale and Squaring Arm12" and 24" Brakes

|

|

Hydraulic Hold Down |

|

Unequal Leg Angle Blades |

|

Rod Shear(Watch Movie) |

|

Offset Die Holder(Watch Movie) |

|

6" x 6" Die Holder |

|

Urethane Stripper |

|

Channel Shear(Watch Movie) |

|

Rectangle Notcher |

|

12" & 24" Brake*Back Gauge sold separately. (Watch Movie) |

|

Laser Light |

|

48" Back Gauge(Watch Movie) |

|

Tube Shear(Watch Movie) |

|

Picket Tool(Watch Movie) |

|

90��° V-Notcher(Watch Movie) |

|

Pipe Notcher(Watch Movie) |

|

Open End Brake(Watch Movie) |

Proud American Manufacturer

Proud American Manufacturer

Est. 1967

All of our products are designed to increase production, accuracy, and efficiency for our customers. We offer in-house financing and a best-in-the-business warranty on Ironworkers, Cold Saws, Band Saws and Tube & Pipe Notchers.

All of our products are designed to increase production, accuracy, and efficiency for our customers. We offer in-house financing and a best-in-the-business warranty on Ironworkers, Cold Saws, Band Saws and Tube & Pipe Notchers.

Our knowledgeable, friendly staff is available to answer any questions or help you find the right product for your needs. Contact Scotchman today

Our knowledgeable, friendly staff is available to answer any questions or help you find the right product for your needs. Contact Scotchman today

.png) Scotchman has leasing plans to fit your needs. Plans ranging from 1 year to 5 years are available. Scotchman's leasing programs

Scotchman has leasing plans to fit your needs. Plans ranging from 1 year to 5 years are available. Scotchman's leasing programs